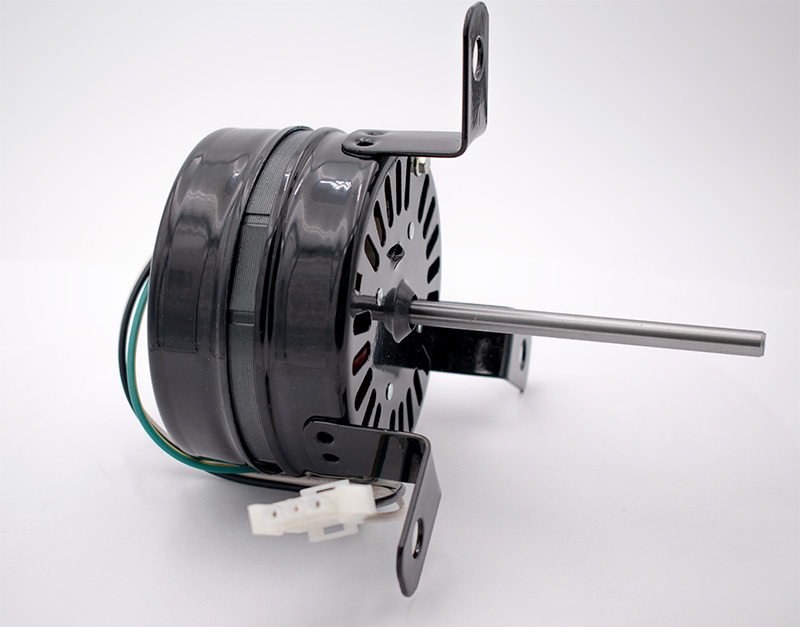

2782S

$195.00

Model Number: F0408B2782

Customer P/N: 303039

Motor Information: 115V, 60hz 0.6 AMP, 1/120 HP, 1100 RPM

| Weight | 3.99 lbs |

|---|---|

| Dimensions | 11 × 11 × 10 in |

Shipping Details

This motor will be shipped from Woodville, Wisconsin via UPS Ground. ALL Orders placed by 12 pm Central Time will ship out the same day the order is placed. All orders received after 12pm Central Time will ship out the next business day.

Wisconsin residents, 5.5% Wisconsin sales tax will be added at the time of checkout.

The replacement motor is identical to the current production motor. The “S” suffix designates the shipping box.

Instructions

Instructions for McMillan Replacement PSC, Shaded Pole, and Brushless DC Motors – Comprehensive Guidelines for Safe and Effective Motor Replacement

These instructions provide guidance for the installation and proper wiring of McMillan replacement Permanent Split Capacitor (PSC), Shaded pole, and Brush Free DC (BFDC). Observing these instructions will help ensure electrical safety, optimal motor performance, system longevity, and compliance with industry standards.

Only trained and qualified professionals should install or service the motor or unit. Failure to follow these guidelines may result in injury and/or void the warranty.

Safety Precautions

- Personal Protective Equipment (PPE): Wear appropriate PPE such as safety glasses, insulated gloves, and protective footwear.

- Disconnect Power: Always turn off and lock out the power supply at the main electrical panel before starting any work on HVAC equipment.

- Verify Absence of Voltage: Use a non-contact voltage tester or multimeter to confirm that all terminals are de-energized.

- Follow Manufacturer Instructions: Consult both equipment and motor manufacturer documentation for specific installation requirements.

- Comply with Local Codes: Adhere to all local and national electrical codes (e.g., NEC, CEC) and HVAC standards.

Removal of Old Motor

- Disconnect power and ensure the system is safe to work on.

- Note and label all electrical connections and terminal locations before disconnecting wires from the existing motor.

- Observe and document mounting orientation and hardware used.

- Remove mounting bolts or brackets and carefully extract the old motor from the unit.

- Inspect the fan blade or blower wheel for damage or excessive wear, replacing as needed.

Selection of Replacement Motor

- Ensure the replacement motor matches the original in voltage, phase, horsepower (HP), frame size, shaft size, rotation, and mounting type.

- For PSC and shaded pole motors, verify capacitor rating (if applicable) and motor speed (RPM).

- For brushless DC motors, confirm compatibility with HVAC controls and communication protocols.

Installation of Replacement Motor

- Insert the replacement motor into the mounting bracket or cradle, ensuring the shaft is properly aligned with the blower wheel or fan blade.

- Secure the motor using original or manufacturer-approved hardware.

- Check for free rotation of the shaft and clearances with adjacent components.

Wiring Instructions by Motor Type

Permanent Split Capacitor (PSC) Motors

- Capacitor Connection: PSC motors require an external run capacitor. Connect one terminal of the capacitor to the designated terminal on the motor (often marked “CAP” or “C”). The other capacitor terminal typically connects to the line voltage (usually “L”).

- Line and Neutral: Connect the live (L) and neutral (N) wires to the correct terminals as indicated by the wiring diagram.

- Speed Selection (if multi-speed): Identify the speed wires (commonly color-coded: black for high, blue for medium, red for low) and connect the desired speed to the power source, capping off unused wires.

- Grounding: Attach the green or bare ground wire to the motor frame or dedicated ground terminal.

- Double-Check Ratings: Ensure capacitor value (μF) and voltage rating meet the motor’s specifications.

Shaded Pole Motors

- Simple Wiring: Shaded pole motors do not require start or run capacitors and are typically two-wire connections for single-phase AC power.

- Line and Neutral: Connect the incoming line and neutral wires to the respective terminals on the motor.

- Polarity: Shaded pole motors generally have fixed rotation; consult the nameplate or diagram if reversal is needed (often not possible without internal restructuring).

- Grounding: Attach the ground wire to the motor frame or ground terminal.

Brushless DC (BLDC) Motors

- Power Connections: Connect the supply

- voltage (DC or AC as specified) to the “+” and “–” terminals on the controller.

- Signal Wiring: Attach control wires for speed and direction (e.g., 0–10V, PWM, or communication bus such as Modbus/BACnet) according to the controller’s wiring diagram.

- Feedback/Monitoring: Some BLDC motors have feedback wiring for tachometer signals or fault monitoring. Route and connect these as instructed.

- Grounding: Ensure the motor is properly grounded.

Common Wiring Diagram Symbols

- L/L1/L2/LINE: Line voltage

- N: Neutral

- GND: Ground

- CAP/CAPACITOR: Capacitor terminal

- COM: Common

- HI/LO/MED/Speed _: Speed selection terminals

- SIG/CONTROL: Signal input

Final Inspection and Testing

- Verify all wiring is secure and connections match the provided diagrams.

- Recheck all connections for tightness and correct placement of speed selection wires and capacitors (where applicable).

- Ensure all covers, guards, and access panels are reinstalled.

- Restore power and observe the motor startup. Listen for abnormal noises and check for smooth operation.

- Measure voltage and current draw to verify operation within specified ranges.

- Verify correct rotation; reverse if necessary and possible (PSC and shaded pole motors only if equipped for reversal).

- Observe the system through a complete cycle to ensure reliable operation.

Troubleshooting Tips

- Motor Does Not Start: Check for power at the terminals, improper wiring, blown fuses, or tripped breakers.

- Incorrect Speed: Verify speed selection lead wiring and capacitor value (PSC).

- Excessive Noise or Vibration: Inspect mounting alignment and shaft coupling; check for debris.

- Overheating: Confirm proper voltage, airflow, and that motor is not overloaded.

Maintenance Recommendations

- Regularly inspect electrical connections for signs of corrosion or looseness.

- Keep the motor and surrounding areas clean and free of dust or moisture buildup.

- Lubricate bearings as specified (some motors are permanently lubricated).

- Periodically check capacitor health on PSC motors.

- Monitor temperature and performance during regular operation.

Best Practices and Warnings

- Replace all wiring and components with those of equal or better rating.

- Never substitute a motor of lower voltage or horsepower rating than specified by the OEM.

- Do not bypass or omit safety devices, such as fuses or overload protectors.

- Label all wires and document wiring changes for future reference.

- Consult a licensed HVAC technician or electrician if in doubt about any installation step.

Documentation and Resources

- Keep all manuals, wiring diagrams, and purchase records for future servicing.

- Record installation date, motor serial number, and key specifications in your maintenance log.

- Refer to manufacturer websites or technical support for up-to-date wiring diagrams or troubleshooting guidance.

This instruction sheet is intended as a general guide. Always defer to the manufacturer’s recommendations and local codes, as specific requirements may vary by equipment and application. By following these instructions, you’ll help ensure the safe and reliable operation of your McMillan replacement PSC, Shaded Pole, or Brushless DC motor.

Related products

HVAC

HVAC

HVAC

HVAC

HVAC

HVAC

HVAC

Attic Ventilation